Abstract

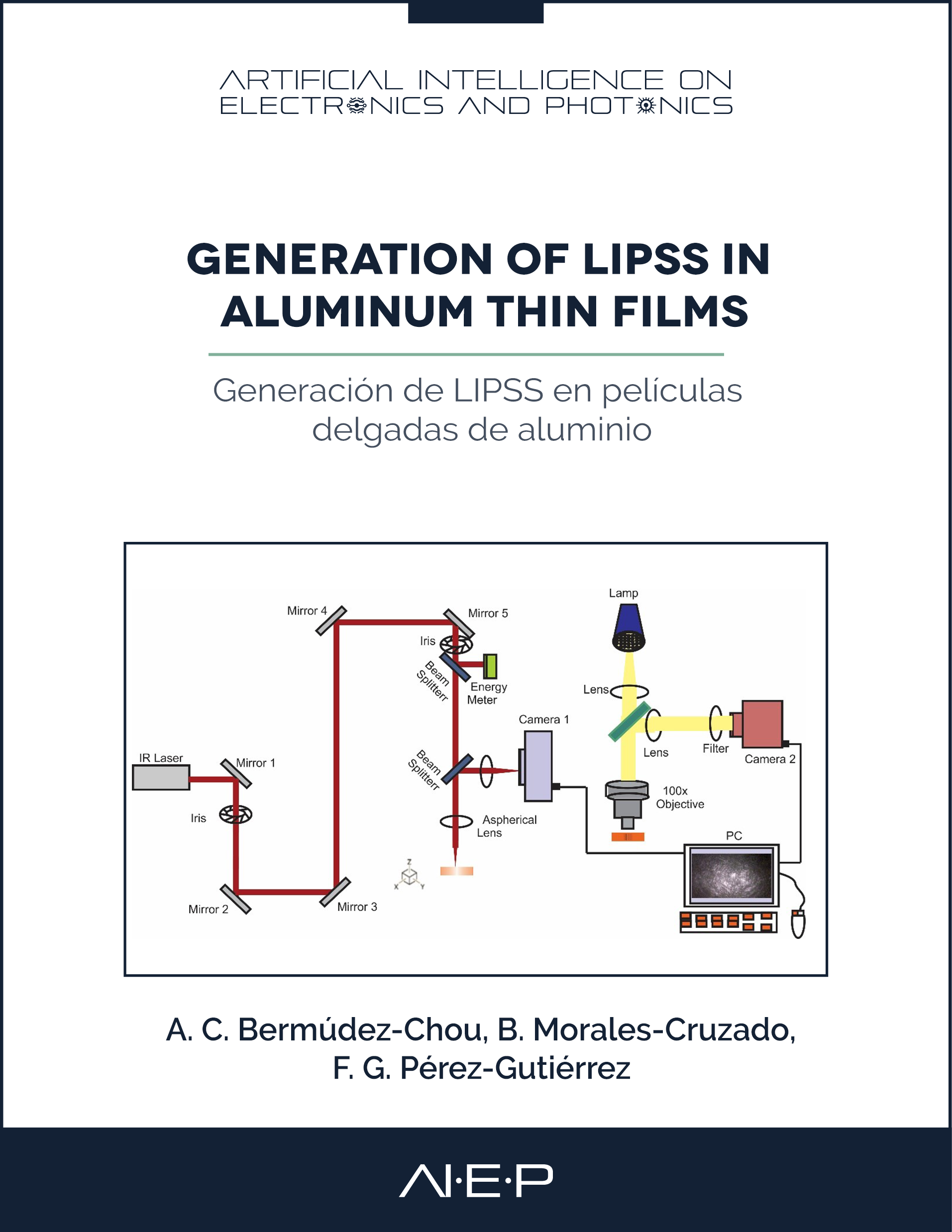

Laser-Induced Periodic Surface Structures (LIPSS) have been reported in the literature for over three decades. These structures can be generated in almost any material. These structures can control the surfaces’ optical, chemical, electrical, and mechanical properties. It has been shown that the spatial characteristics of LIPSS depend on the material’s optical, thermal, and physical properties (such as roughness r) and irradiation parameters. The main parameters that influence these characteristics are periodicity Ʌ, height H, and orientation. This work aims to investigate the creation of LIPSS in thin aluminum films. For that, an experimental setup to fabricate these structures was built. The model consists of a six ns pulsed IR (1064 nm) laser with energy up to 20 mJ. Laser scans were created at a speed 8 μm/s (Neff = 4) with frep = 1 Hz and Fp = 16.2 J/cm2, with a separation distance Δγ = 60 μm on thin aluminum films. The substrates used to deposit the Al thin films were 8 mm × 40 mm, while the thickness of the thin films was 1 μm. The resulting structure is 300 nm deep.